Osiris Innovations

Helping you launching your manufacturing business

Improve Your Manufacturing Operations

Helping you from Idea stage through taking your product to market

Manufacturing Consultancy

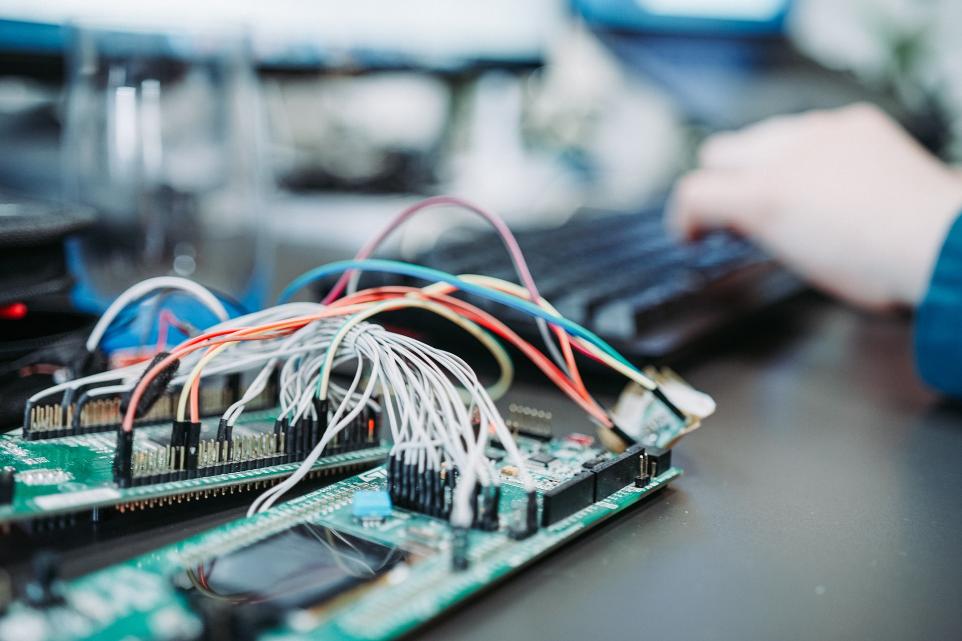

Product Design

Manufacturing Aiding tools

Turn Key projects

In

Manufacturing Industries

We Serve

New Factory Set-Up

Project Management

Launching a new factory on time and

within budget requires careful planning and execution. Through facility

construction, equipment installation, or even workforce training, our

specialists can assist in developing and managing a feasible timeline across

multiple stakeholders.

Site Selection

with

countless industrial hubs for manufacturers to choose from. CMC’s experts are

familiar with the Chinese manufacturing landscape and can help you select the

perfect location based on your budget and operational needs

Building and Overall Layout

Considering

your facility’s material flow and internal logistics at this stage will help

your business maximize productivity in the long run. We consider every part of

your production process to determine the best equipment and layout for your

needs—aiming to reduce overall risk and save costs down the road

Process Development

Here, our consultants dive deeper into

the details of your operations. At this stage, we help you decide your

requirements for equipment reliability and automation; how to arrange

workstations for maximum efficiency; and how to ensure processes are tightly

linked for lower costs and shorter lead times.

Hiring & Training

A successful factory launch requires the

right people in the right places with the right skills. CMC can assist in

determining how many employees are needed; what qualifications they should

have; and how to hire, evaluate, and train them in time. This is also a great

time to develop a company culture and test your equipment with your employees.

Factory Launch

On the home stretch, it can be easy to

let your guard down but many things can go wrong at this stage: suppliers not

delivering on time, equipment not working as expected, and so on. With a launch

date quickly closing in, our experts can quickly troubleshoot issues and decide

the next best steps to make your factory launch as smooth as possible.

New Product Introduction steps

1- What type of new product

introduction process is appropriate?

The

more “new and untested” the new product design is, the more ambitious your

project, and consequently the more help you and your supplier will need. This

first step will influence the approach of all subsequent steps

2- Supplier selection

Can you use one of your existing suppliers, and how much will they need to adapt their processes? Or do you need to search for a new supplier, and in that case what criteria should you be looking at? Our consultants can help evaluate the risks related to potential suppliers.

In case you are working in a new company

starting to manufacture in China, we cannot over-emphasize the importance of

suppliers and sub-suppliers — they are probably the main cause of new product

introduction delays.

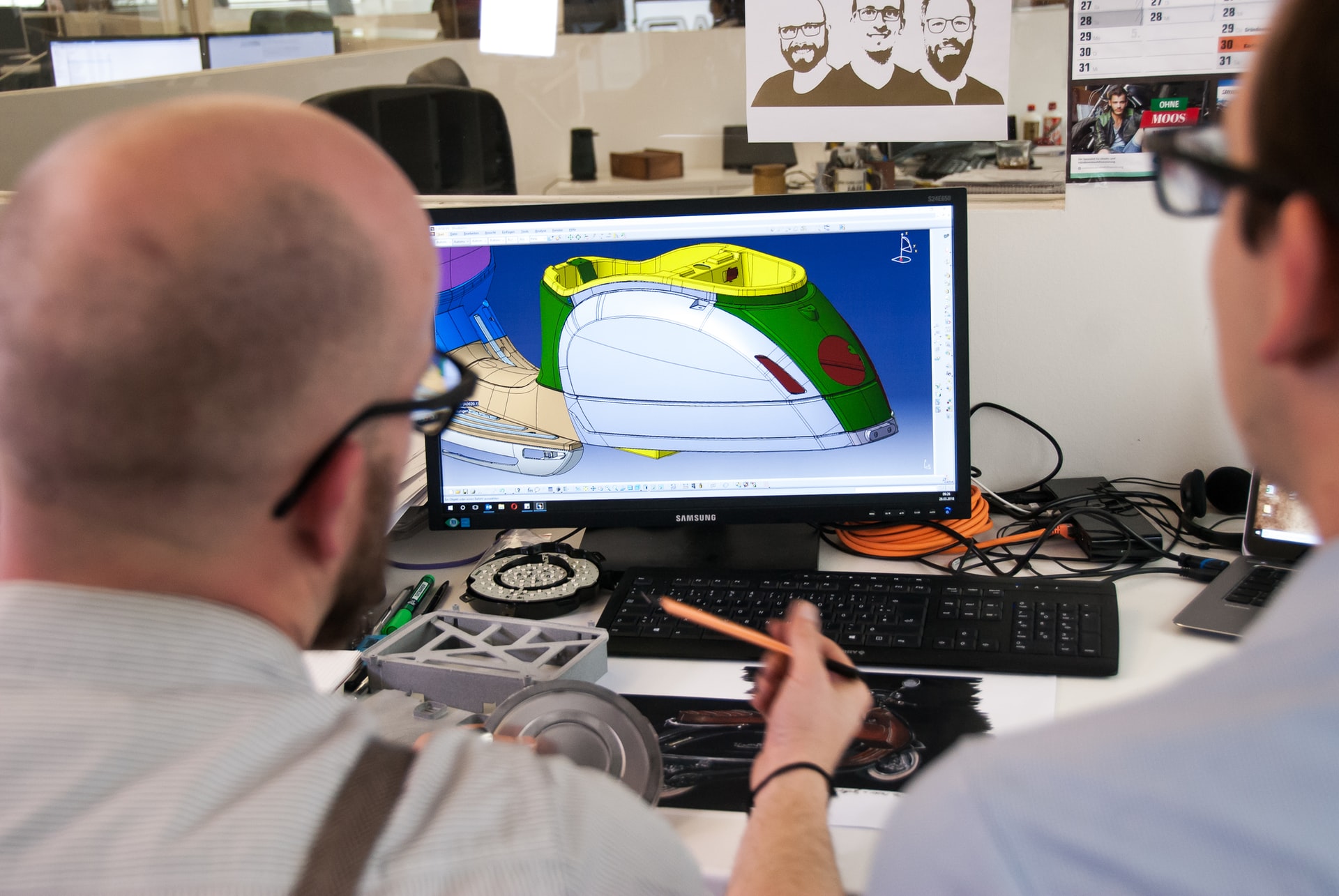

3- Line arrangement

Let’s say you have selected a main

supplier that will take care of some fabrication/machining as well as assembly

and testing. Have they set up their processes in a way that will make it easy

to reach your quantity and quality requirements? Maybe they have not dedicated

some lines to your new product — in that case, will this cause issues? We can

assess their line setup and provide suggestions for improvement.

4- Employee Training

If your product is different from what the factory usually manufactures in at least one significant way, the people who will work on your product need to get some training.

This

is an area most Chinese manufacturers tend to overlook, and it has serious

implications at the time of production launch. The reason is, factory

management doesn’t want to slow down their regular production schedule. But

there are easy ways to get workers trained, for example on a small NPI line on

the side.

5- Testing the processes

Making a few pre-production samples does

not uncover all the issues that you will face once mass production is launched.

One of the steps of the PPAP

(Production Part Approval Process — an approach very common

in the auto industry) is to force the line to “run at rate” for a certain

time. It is the only way to find many of the issues that might affect mass

production and to fix them without delaying the first shipment.

6- Going live

There are several ways to “go live”. Depending on the complexity of the product, production rate might have to be ramped up progressively and special measures might have to taken in order to ensure quality is good.

If steps 1 to 5 were done right, step 6

should take place at the expected timing and should not uncover serious issues.

It means that following the process we outlined above is the best way to get

your new product made and launched with favourable results.

Production Planning, Supply Chain Management, Warehouse Management, ERP Consulting

Production planning

A good planning system allows the factory to pull the components, materials, and people that are needed at the right pace to meet the demand from customers in the most cost-effective manner.

It means work in process and finished

goods do not get built too far in advance (causing many types of waste:

overproduction, extra inventory to move and store…) and your on-time delivery

is good. It also means your operators are held up to standards and have

objectives to meet, and they seldom stay idle because of a shortage of

materials from the upstream process.

Purchasing & Supply Chain

Management

This is often an extremely sensitive topic in Chinese organizations, but it is critical that purchasers support the production plan. Our consultants often see large batches purchased many months in advance, with the objective of getting a discount from the supplier. This practice ignores many of the hidden costs of excess inventory.

In some situations, the price of a key

commodity fluctuates widely (e.g. leather). We help purchasers take

decisions based on the total cost of ownership and based on past fluctuations,

rather than based on a unit price.

Warehouse management

Inventory control is a key activity in the fight against aged inventory that might turn into scrap. Simple metrics can help warehouse staff, purchasers, and planners keep inventory levels low.

We

can also help a factory by making its warehouse and internal logistics

operations more efficient. Investment needed is often low (a simple ERP system,

as well as a barcode system, can go a long way in reducing the amount of

manpower needed to handle components and register every movement).

ERP Consulting

An appropriate ERP for your operations will give you visibility into purchasing, warehouse, and production, among others. And it will reduce a lot of manual work in your office.

We can support, from the users’

perspective, the implementation of a complex ERP (e.g. SAP, Oracle) as well as

much more simple ERPs. Different types of ERPs are appropriate for different

businesses, so in our ERP consulting China service we can also recommend which

solution is best for you.

50,000 people, run Clean to grow their financial wealth.

Join them and make the right money move.